Liquid rubber is a revolutionary product that is changing construction projects worldwide for the better.

Though it has been around for quite some time, liquid rubber has recently advanced to allow it to be used in many different applications.

Thanks to its safe, non-toxic formulation, not only do large-scale companies use it for their commercial spaces, but homeowners and small businesses do use it as well for refreshing the look of their properties.

If you are eager to learn more about this awesome product, let’s dive in…

What's Here in the Article:

What is Liquid Rubber?

As in the name, liquid rubber is a multi-purpose water-based liquid coating that hardens into a strong waterproof membrane once applied and allowed to dry correctly.

The idea of liquid rubber is not new and has instead been around for a few centuries when bitumen was combined with items like straw, jute, and rag felt to create waterproof roofing for different structures.

Only around one century ago, liquid roof coating manufacturing began to crop up as a commercial endeavor.

Even then, it took until the 1960s for emulsions, acrylics, and unsaturated polyesters to be readily used, bringing about higher-quality products and better roofing.

In the 1980s, polyurethane coating was developed, and this particular chemical composition is the base of Liquid Rubber.

What Can it Be Used For?

Liquid Rubber is most commonly used as a protectant against corrosion, as an air barrier, and as a way to waterproof surfaces.

The coating sticks to virtually any surface that is not oil-based, including stone, concrete, wood, bitumen, metals, zinc, and PVC in any shape or size. So, you can not only use liquid rubber for coating your deck but also for the roof, driveways, pathways, garages, etc.

After it is applied to a layer, the compound then cures to create a rubber-like, seamless, flexible, and elastomeric waterproof membrane.

It can be stretched and then returned to its original state without any damage occurring. Because it is seamless, there are no joins where traditional waterproofing efforts can fail. It also makes it easier to use it in stranger places, like the side of buildings or under a bridge.

How to Apply Rubberized Deck Coating?

While it may sound difficult, applying this product is not so tough if you know the process.

First, you must prepare the surface by cleaning it and ridding it of any oil, dirt, or dust. Ensuring the surface is clean and dry before applying the liquid rubber will prevent any barriers between the surface and its compound, allowing the product to adhere properly.

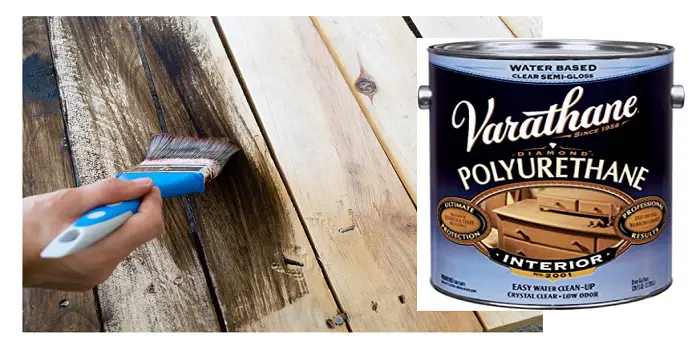

Once you have prepared the area, a liquid rubber coat can be installed on the decking like any other type of water-based paint by using tools such as a spray gun, roller, or brush. You can even apply it right on top of any old coat of liquid rubber.

The only materials liquid rubber coating can’t be applied to are silicone, certain kinds of shiny or smooth surfaces, and oil-based paints or varnishes.

Apply a minimum final thickness of a single gallon for every 40 square feet in three or four thick coats. Any porous or high-traffic areas will need a gallon for every 30 square feet.

Once you are done, you can expect that the product will take around 20 hours to dry in conditions of 20 degrees Celsius.

Is Liquid Rubber Safe to Use – How Long Does it Last?

Liquid rubber is water-based, so it’s quite a safe product to use.

There is no need for protective clothing to stay safe, but because it can be difficult to wash out of clothing, it’s recommended you wear old clothing and a pair of gloves.

If you do end up getting some on your skin, it isn’t toxic and can quickly be removed using baby oil.

The fumes aren’t dangerous, but it is still recommended that you wear a mask should you be in an unventilated area.

Of course, every circumstance is different, but you can generally expect to need to reapply it once per decade. Degradation will occur based on different factors like corrosive substances and UV rays. Checking it visually will be the best way to see if it is wearing down.

How Does it Compare to Other Types of Wood Decking Finishes?

Liquid Rubber decking is a budget-friendly, smart way for homeowners to waterproof decks.

Unlike oil-based paints, stains, or varnishes, it is simple to repair and clean. Vinyl decking will, however, require frequent patching that is usually quite evident once it dries.

Furthermore, liquid decks have no seams, unlike many other types, so you can have peace of mind that it is waterproof.

Do keep in mind that it requires specific conditions to be applied, including no excess moisture, no exposure to direct sunlight, and no cold temperatures. So, if you are planning for a refreshed look of your deck by giving it a recolor, this can be your product.

Share the post "What is Liquid Rubberized Deck Coating – Is It Safe to Use?"

Douglas Becker (aka Painter Doug) has over twenty years of experience as a painter in Adkins, Texas. At present, he resides in Florida with his family.

From painting multi-storeyed houses, condos, and apartments to large commercial buildings and small offices, he had served various customers in areas not only in Adkins but also in Southwest Florida, Sarasota, Naples, and many more. To know more about him check here.